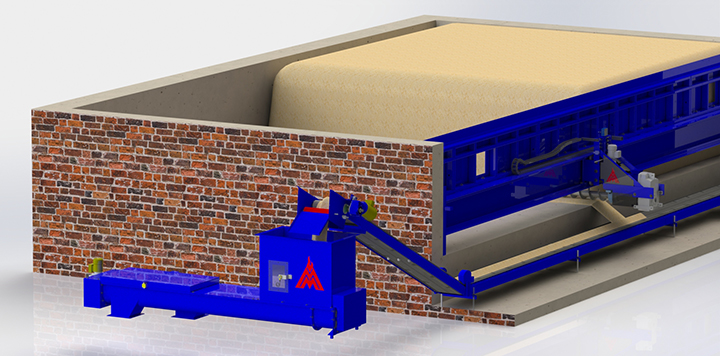

Messersmith Traveling Auger System

The Messersmith traveling auger system is a low cost solution to many material handling problems. Proven technology ensures that each installation will provide years of dependable operation with many user friendly options.

Equipment Options

• Traveling Auger

• Belt Conveyors

• Screw Conveyors

• Material Storage Bins

• Metering Bins

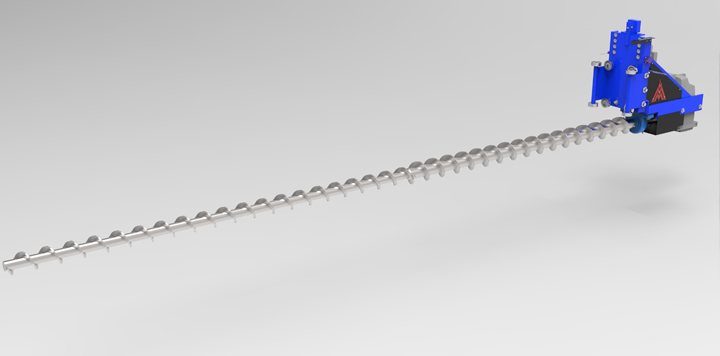

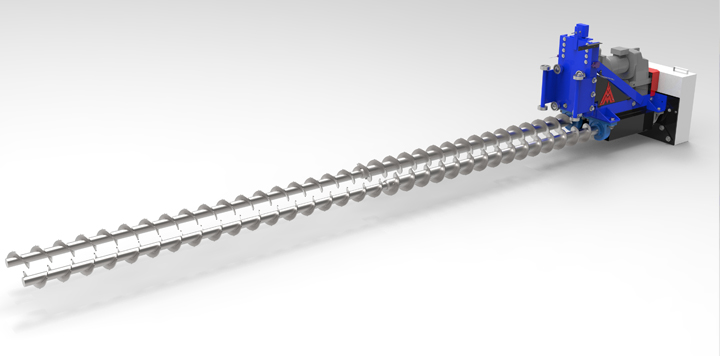

Traveling Auger

The Messersmith traveling auger is the low cost solution to many material handling problems. Material bridging and jamming is not an issue with a Messersmith traveling auger. There are no restrictive points to cause material jams. The traveling auger traverses the entire length of the storage bin, thus undermining and releasing any bridging of material. The traveling auger has carbide teeth on its perimeter to help break up frozen material. It can operate in material depths up to 20’.

The traveling auger is easy to maintain. There are no filters or dripping seals to replace, no hydraulic fluid leaks to clean up and no pumps to rebuild. No oil coolers are needed in the summer months. Periodic greasing of bearings is the primary maintenance requirement.

Low energy consumption is a hallmark of Messersmith systems. The traveling auger only needs 5 HP to operate. When a traveling auger is teamed with conveyors and metering bin, the total horsepower required is often less than 10 HP.

Metering Bins

Metering bins provide short term material storage and variable material flow. Process driven material modulation is made possible by the PLC in the control panel. The PLC dictates the rotational speed of the metering augers. Dependable sensors are part of the metering bin system. They control material delivery from the traveling auger and belt conveyor, thus keeping the metering bin full.

These rugged equipment components are paired with the latest control technology to provide a long lasting, easy to use system. The control panel monitors the operation of all augers and conveyors to confirm proper function.

Belt Conveyors

Belt conveyors are available to work with a traveling auger and provide dependable, cost effective material transfer. Low energy consumption minimizes operational cost. A material sorter is built into the conveyor system to remove over length material. This will minimize jams in downstream augers by keeping large pieces out of the metering bin.